The terms laser cutting, etching and engraving are often used interchangeably, but each process offers different metal fabrication benefits. All three provide a permanent way to mark products with company logos, serial numbers and designs. While it seems as these processes accomplish the same goal, how each goes about it is different, and one may work better for a particular metal or project over another.

The main difference between cutting, etching and engraving is the lens focal length. A laser-engraving machine has a shorter focal length, which results in high quality detail work. A laser cutter, on the other hand, uses a longer focal length, which allows for cutting thicker materials with a more precision cut and at faster speed.

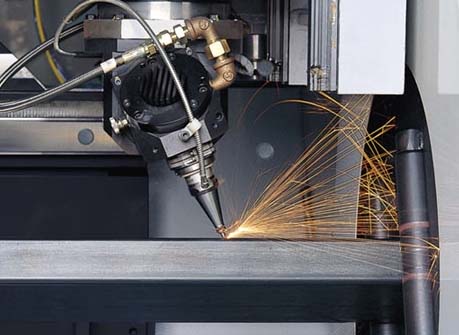

Laser cutting is an industry standard for accurate, fast fabrication. A high-powered laser is able to make precision cuts in sheet metal by actually melting the metal. High-pressure gasses, typically nitrogen or oxygen, are used along with the laser beam, and the cutting head moves over the metal plate to create an exothermic reaction that delivers the precision cut details.

We often get asked if our 4,000-watt flat laser-cutting machine can etch materials. It can, but a laser engraver, designed specifically to etch and mark materials, can do the job better. The flip side is that a laser-engraving machine isn’t really designed to cut materials. While both machines serve essential functions, they’re not as cross functional as people may think.

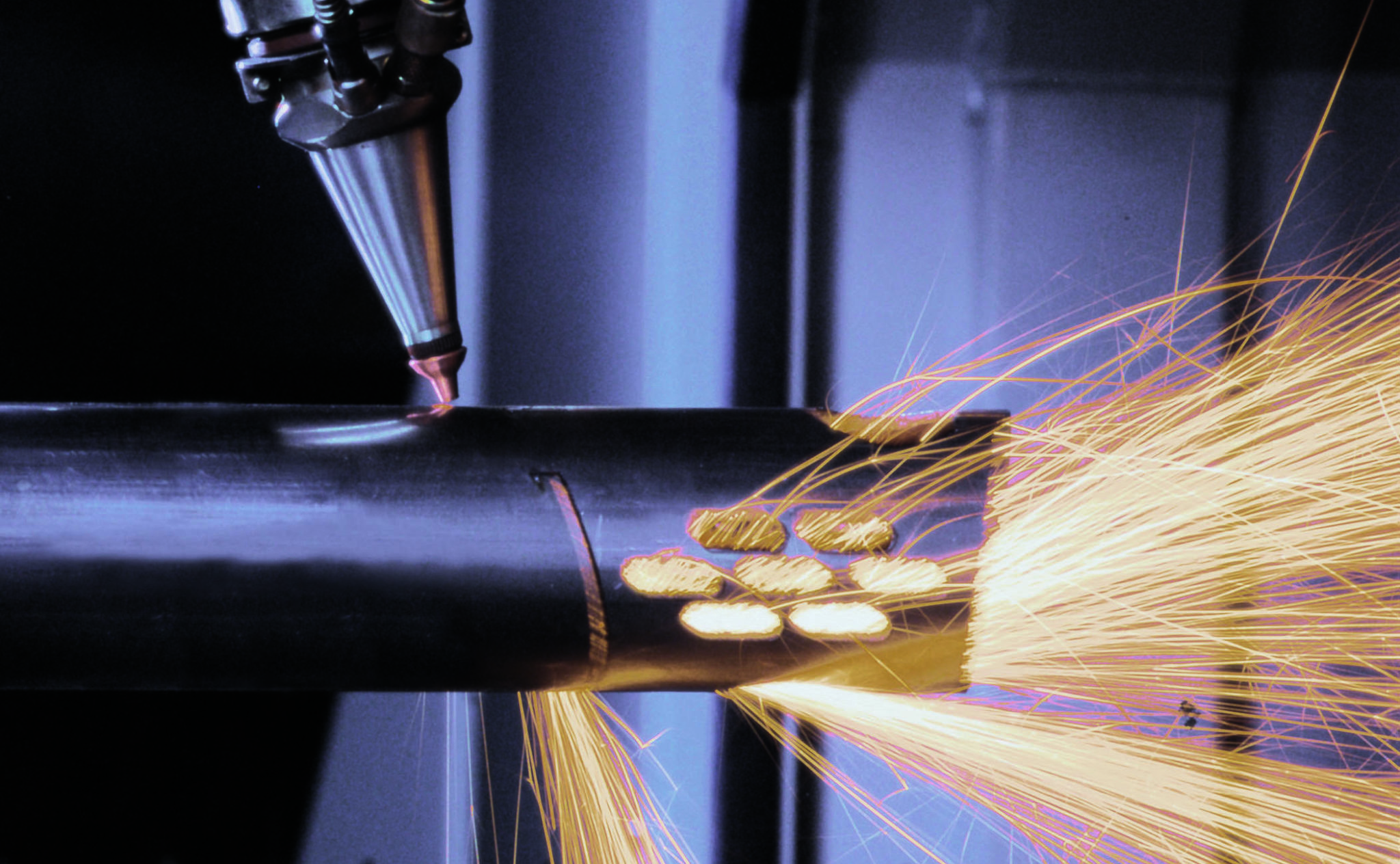

The Mazak Fabrigear II 220 tube laser is the latest addition to the All Metals Fabrication family of laser cutters. Designed for fast, high-precision cutting, this revolutionary tube laser boasts 4,000 watts of power and a tapered laser torch that allows for the laser cutting head to cut any shape, size or extrusion. Click here to read about the significant advantages our new tube laser offers.

Tube laser cutting is very similar in the actual laser beam technology, but differs significantly from flat sheet lasers with the ability to cut full 24-foot lengths of tube, angle, channel, beam, etc. without requiring the very manual setup that flat sheet lasers need to cut the same extruded type of material.

Ultimately, cutting lasers and etching lasers are really designed for two different purposes and are both important and useful technologies in the fabrication industry.

AMF is the only fabricator in Utah that has water jetting, flat sheet lasering and now tube laser capacity under one roof. Call us or email us at info@allmetalsfab.com to find out how tube laser cutting can enhance your next metal fabrication project.