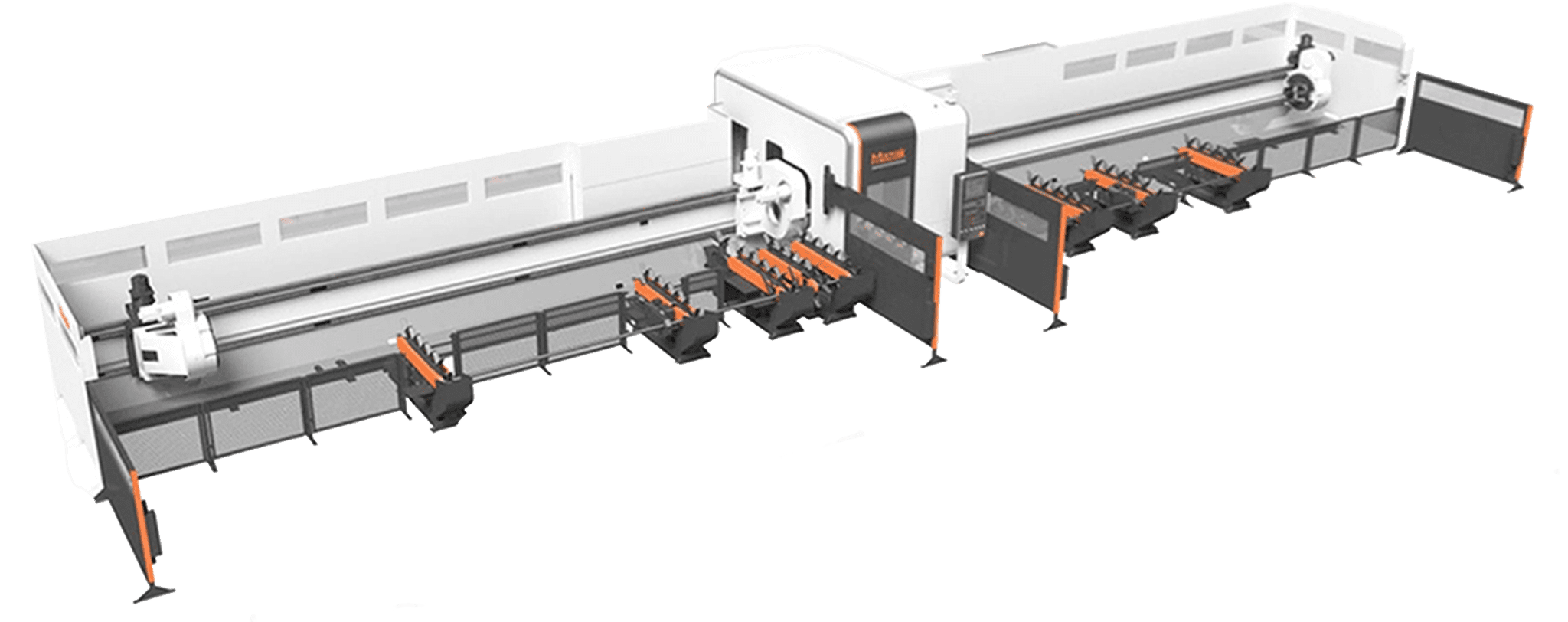

All Metals Fabrication’s dedicated 60-foot tube laser cutting technology that delivers the most advanced tube laser cutting technology available in today’s fabrication industry. Introducing the Mazak Fabrigear II 220 tube laser – a cost-effective and reliable laser tube cutting machine. Its efficiency makes it a valuable addition for first-time users and as a supplementary machine. Designed for super-fast, high-precision laser tube cutting machines solutions, the Mazak Fabrigear II 220 tube laser cutting technology, built for maximum productivity blows away traditional sawing, coping, drilling and punching processes. Increased speed and precision saves tons of money and time on downstream costs and assembly that benefits customers.

Our laser tube cutting services offer a range of benefits that can transform your manufacturing processes. Explore the world of laser tube cutting with our ideal solutions. Learn how lasers can streamline operations by eliminating entire process steps while expanding your part production capabilities.

Laser tube cutting technology, with 5-axis tube cutting, is turning traditional fabricating methods upside-down that deliver money saving optimal results. You can save significant time, money and floor space by utilizing this amazing tube laser cutting technology—let us show you how!

Well, imagine all the speed and precision of a flat laser cutting on flat materials now used exclusively for shape materials. Round tube cutting technology or square laser tube cutting technology, naturally, makes sense, but don’t forget about channels, angles and even unique shapes like obrounds, T-shapes and I-shapes tubing.

Forever, fabrication shops have been frustrated by the very slow, very manual process of placing holes, obrounds, specialty cuts and miters laser cut parts on tube and pipe shapes. It takes a long (as in looooong) time, and the accuracy is always suspect! Tube lasers are a dream come true for both fabricators and customers. In short, the tube laser cutting technology save time, save money, optimize operation and increase project quality—all in one shot!

Regardless of the complexity of your product, your primary objective remains straightforward: being the first to market. If your goal is to outpace the competition and bring your product to market faster, our laser tube cutting services at All Metals Fabrication are the solution you need. Lead Times with laser tube cutting services No matter how complex your product is, your number one goal is simple: to get there first.

Lengths and various structural shapes are usually hard to manage, hard to move around the shop and hard to fabricate. Besides tube, think about angle, length and channel. Any custom angle cut, any custom mitre, any hole or slot can be done so much easier on the laser tube cutting project vs old methods.