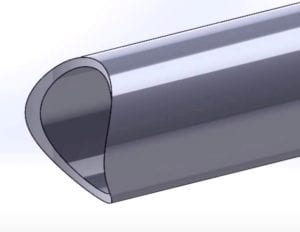

Most of the world is familiar with metal roller coaster tracks. They round-shaped chunks of tube with crisscross pieces attached all along the track and often look like DNA strands twisting and turning high up into the air for all riders to excitedly, or fearfully, see and hear as the speeding cars race, again and again, through the ride.

The thunderous noise, as they rise, plummet, twist and turn, creates excitement as the many riders are screaming in happy terror.

Old roller coasters, one might notice, are notoriously rough, bumpy and jolt the riders from side to side. New roller coaster, on the other hand, are amazingly smooth. The difference in ride quality can be attributed to many things but perhaps the biggest difference is that roller coaster tracks are manufactured, in these days of modern fabrication technology, with amazing accuracy.

Tracks that were once chunked together haphazardly are now welded together with amazing precision.

Part of that precision originates with the cut quality of the track itself.

AMF’s dedicated 60’ foot, 5-axis, tube laser has cut these heavy round, or square, pieces of tube within .010 of an inch (that is fractional equivalent of less than 1/64), which is a dimension the human eye nor normal tape measure cannot even decipher.

AMF’s Tube Laser not only cuts these pieces almost perfectly, is also, using its 5-axis technology, can cut the miter on the tube making it ready to weld.

Old fashioned techniques to do this same thing would require the following steps:

1) Saw cut the tube

2) Create a hand pattern and trace the cope lines on the tube

3) Hand plasma the line to create the cope shape on the tube end

4) Grind the coped tube end to create a groove for welding

That process is not only very time consuming; it is also very inaccurate (translation, bumpy ride).

AMF’s tube laser will take all those steps and accomplish them at one work center.

The time savings to make the parts using the tube laser is amazingly better—probably four times or five times faster.

However, it gets better, now when the welders begin assembling the winding tracks, the time to weld is often time 100% faster, meaning what used to take 1 hour will now take 1/2 an hour.

Overall, time to fabricate the parts and then the time to weld the parts is shockingly faster when utilizing the benefits of Tube Laser technology compared to old-school methodology.

This not only holds true for roller coaster tracks but nearly anything that comprises tube, channel, angle or pipe. Tube Lasers can cut all these shapes with unbelievable precision and speed. Even more, the weld and assembly will go much faster as well.

There is no disputing the absolute improvement in time and quality, hence our saying, “AMF has a Tube Laser and we are not afraid to use it!”

Take a minute to explore and consider how old technology might be leaving you in the dust—both in terms of price and quality.

We invite you to take the Tube Laser Challenge, meaning get a quote, tell us you want to take the challenge and we will give you another 10% off your price.

All Metals Fabrication fabricates stainless steel, steel, and aluminum. We specialize in industrial & architectural fabrication and can make you a believer in what technology can do to help your metal fabrication projects, like our roller coasters, go faster, smoother and better—no fear required.