All Metals Fabrication (AMF) hit a home run this spring in preparation for this summer’s baseball season at Citi Field. How does a metal fabrication shop in Ogden, Utah win work across the country at this prestigious ballpark? In a couple of words, Tube Laser technology!

The job required a large quantity of square tube frames, but the deciding factor will surprise many—it was actually our tube laser cutting 6x4x5/16 angle that won the job. AMF was able to cut several hundred parts using our tube laser. It was a scoring-fest, so to speak, as we hit through the entire line-up on this unique-sized angle.

Speed and capacity were vitally important, but just as critical was the exactness of the cutting. The job required tight tolerances, +/- .01. The angle iron and the tube support structures had to align precisely—not something an iron worker or drill station could muster. Each piece of angle and each piece of tube had both holes and slots that needed to be precise to hang the overhead displays on the job site.

Most OEMs and engineers still fail to recognize that tube lasers will cut angle. That may be worth repeating—tube lasers cut angle shapes. Also worth noting, tube lasers cut channel, squares, rectangles and even obround shapes.

Gone are the days when accurate holes placed on angle legs are done in mills or drill presses—that is slow and, in the case of the drill press, often inaccurate.

Even better, gone are the days when mills are needed to cut slotted holes in angle or tube shapes. Tube lasers devour slotted holes for breakfast, lunch and dinner!

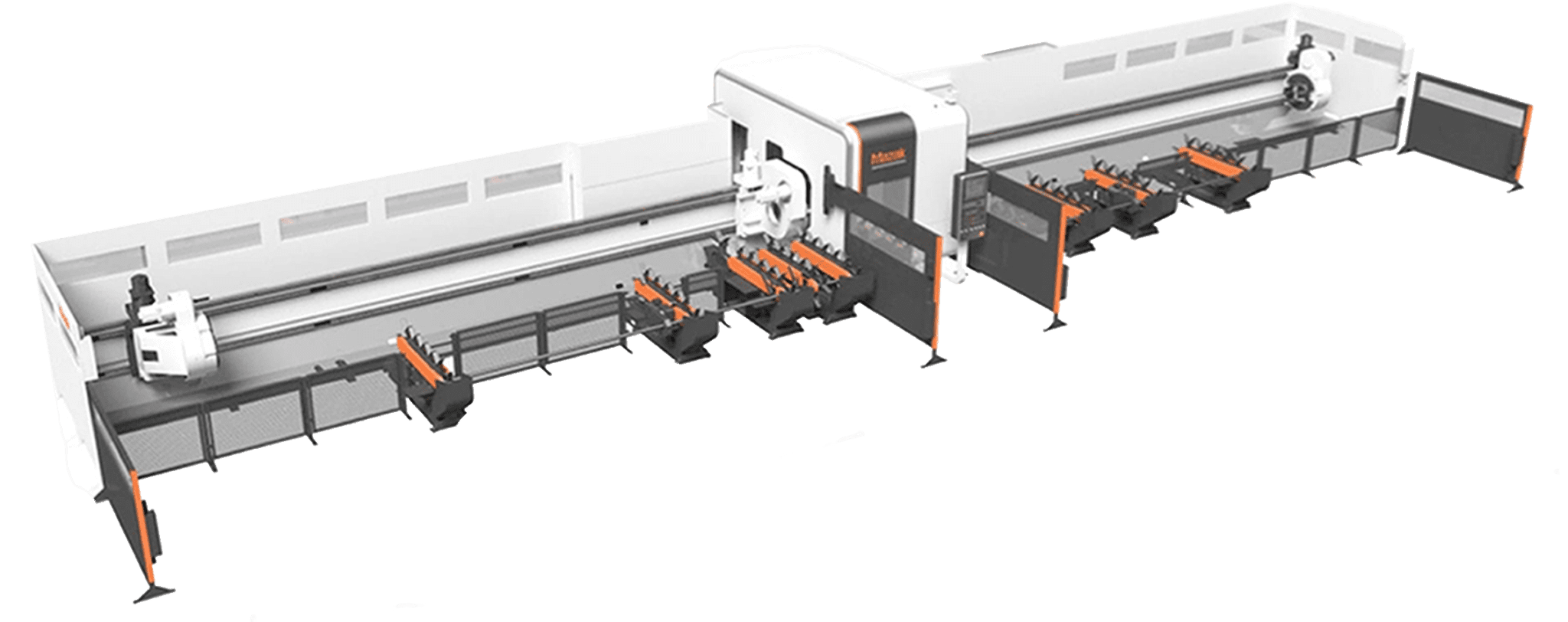

Imagine setting a 24-foot piece of tube or angle on a machine that can pull the entire length of material through the machine, cutting several individual smaller pieces one by one, including slotted holes and miters. Imagine that compared to saw cutting each piece of tube to part length, sending the now cut material to a separate milling station to add holes or slots and perhaps sending it to a third workstation to cope, or angle cut, the tube ends.

One machine, one setup versus three machines, three setups and three material transfers—the comparison is obvious. Tube lasers will win every time.

AMF hit a home run for Citi Stadium and we do that for many customers across the U.S. We have sent our tube laser work to Texas, California, Arizona, Florida and New York. Utah lies at the crossroads of the West and can easily transport parts and pieces anywhere our customers need them.

Learn more at here. We have case studies, features and benefits pages and other information that will help you understand how tube laser work may be a Grand Slam for you.