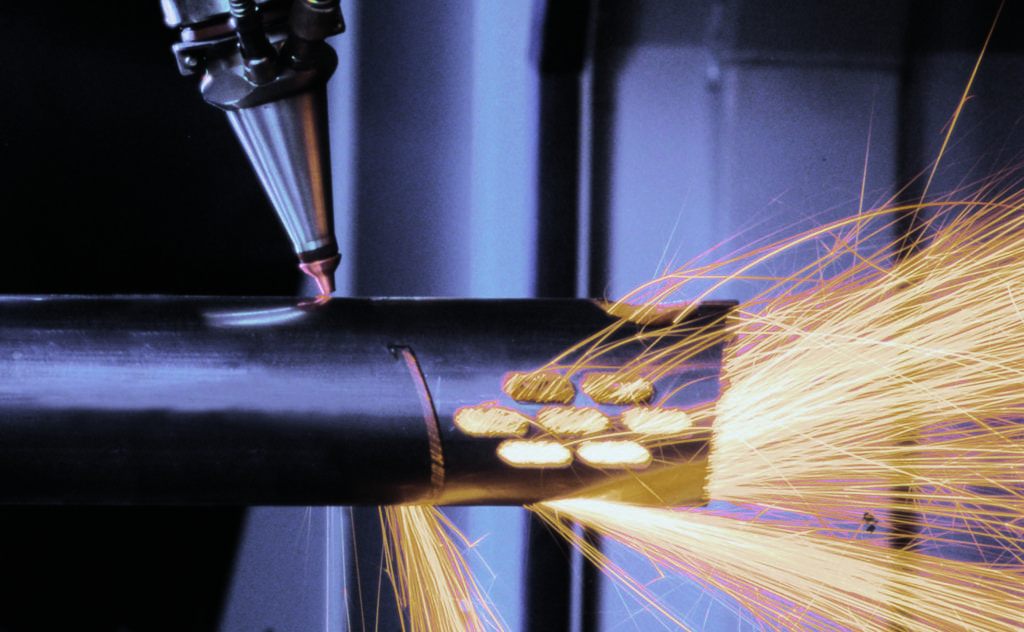

Tube Fabrication has taken giant leaps in recent years with the advent of dedicated tube laser fabrication machines.

Fabricators, in the last few years, have seen significant advancement in this technology. In the past, many flat sheet lasers had add-on components that could cut tube but the setup times were significant and the capacity was very limited.

Today, tube laser technology allows for tube fabrication, cutting and manufacturing that is incredibly fast and extremely versatile.

Most tube lasers will handle 24’ lengths of material to load and off load in the machine. In addition, loading tables are setup to handle large bundles of tube and can often run lights out. Laser cutting through large bundles of tube can be done in hours.

Very often, 24’ lengths will be cut down into several smaller pieces (for example 7 EA parts that might be just over 3’ long). Hundreds of these parts can be processed in hours and cut with laser-quality-precision.

In addition, tube fabrication often requires 5-axis cutting which is impossible on flat laser machines with tube laser attachments.

5-Axis cutting generally means that intricate cutting can be accomplished on round, square, rectangular or angular shapes. It also means the tube can be cut with beveled cut lines or cut lines that are not perpendicular to the surface of the material.

Tube manufacturing that used to require machining is often, depending on tolerances, very manufacturable on a tube laser as well. Cutting slots or multiple-sized holes is extremely easy and very accurate. In most cases, Tube Laser fabrication has no issues holding .010 tolerances.

People in the tube processing, manufacturing and supplying business should learn all they can about tube laser technology.

In many cases, the processing time can be 30-50% less which equates to significant savings on manufactured parts.

Learning what tube lasers can do is also very important.

Saw cutting is likely a better option than tube laser cutting in only one circumstance—if the cuts are straight (or square) and the tolerances are loose. Any structural item that requires miter cuts, angle cuts, coped cuts, holes, slots or high accuracy will be much faster and cost effective on a dedicated tube laser.

Again, any person involved with tube manufacturing, processing or fabrication should take the time to investigate this technology.

AMF’s tube laser will handle up to 25’-6” lengths of material and 8.66” diameter or 6”x6” square size. It will cut steel up to .75” thick and stainless steel up to .375” thick.

Running two shifts, we generally have excellent capacity and can often turn jobs in 3-5 days.

Give us a call and see what AMF’s Tube Laser can do for you!

info@allmetalsfab.com

801-392-9494