Metal tempering is an important part of any metal fabrication operation. To temper, you must heat metal up, a process that changes its chemical makeup. Ultimately, this also makes metals stronger or softer, and allows us to perform functions we previously couldn’t. Here’s how we do it:

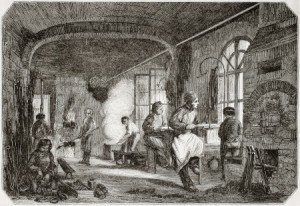

The basic metal tempering process hasn’t changed much since medieval times. First, the metal that you’re working on needs to be heated. This usually requires making sure the entire piece of metal is hot all over. Eventually, the metal turns bright red or glowing orange in color. Once the first heating process is over, the metal is doused in a bucket of water. After it has had time to cool, the metal is then reheated but only on the most important part of the project, or the “focus area.” This second reheating is what’s called “tempering”. Once the metal you’re working with is “tempered”, the metal piece is cooled on a steel surface. As the metal cools, it begins to solidify and increase in durability.

So why does heating and cooling metal cause it to become more durable? There are a couple of reasons: First, the initial heating creates what’s called austuerizing, forming a special alloy that contains carbon and iron. When this auesterized material is dunked in a bucket of water, the metal turns to Martensite. Martensite has crystal-like qualities, which makes the metal stronger than it was before.

Metal tempering isn’t an easy skill to master. It requires a lot of practice and strict adherence to specific temperature guidelines.