Tube lasers do battle with tradition fabrication methods very well!

Sawing, deburring, coping, mitering, drilling are common fabrication processes, but one might question how tube lasers stack up against the likes of traditional machining centers.

The answer—very well.

Frankly, the main issue when comparing a tube laser to a machine center is tolerance.

Dedicated tube lasers are very good at holding tolerances in the +/- .01 range.

The question potential tube laser customers should ask is what kind of tolerance is really required on my part.

Engineers are generally good at designing fabricated parts at +/- .01 and machined parts at +/- .005 (or less) but many times those tolerances are more a result of the engineer’s drawing template then the part requirement. Drawing templates are infamous for creating unnecessarily expensive, high-toleranced, parts.

Many of our customers save significant money by simply asking the engineer if the tolerances can be modified for certain parts that could be done on a tube laser which results in a substantial savings.

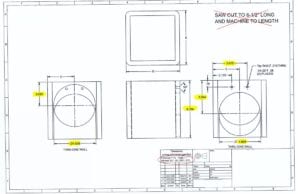

This drawing is a good example. Saw cutting, machining to size and then tapping…verses stacking a 20’ length of tube into a tube laser and letting the machine go to work. In this example, because of the tolerance allocation, the tube laser will essentially replace three work centers and, obviously, will be much faster—both in processing time and material handling time.

Dedicated Tube Lasers are leading edge technology that save people money. Find out more by contact AMF at 801.392.9494 or info@allmetalsfab.com.