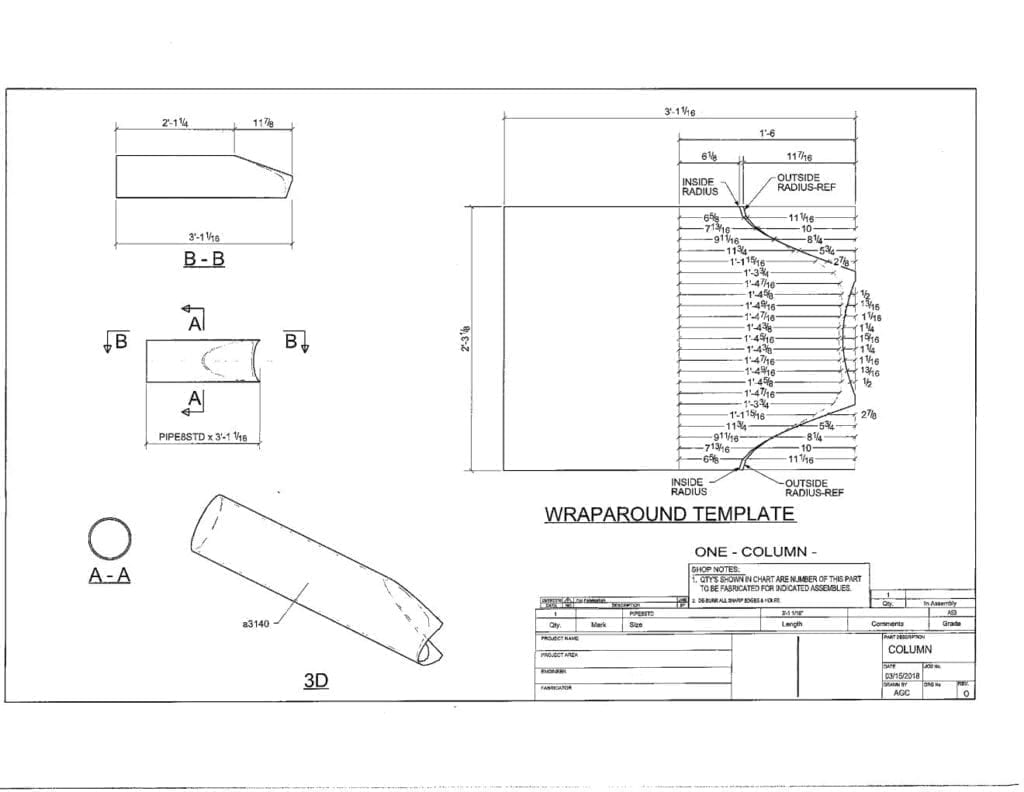

If you are still printing patterns to wrap around your structural tube (see picture) you should really consider the amazing benefits of a tube laser.

Please consider the real hours used in the old-school pattern process:

1) Laying out the pattern

2) Printing the pattern

3) Laying the pattern on the tube or pipe and tracing it

4) Hand plasma cutting the pattern

5) Grinding the jagged cut

6) Grinding the weld prep groove

Depending on quantities, this old-school pattern process could be anywhere from .75 hours to 1.5 hours of work per a piece of pipe end.

At $65.00 per an hour, this little hand-cutting process is running you up to $98.00!

When the process is finally complete, the cut-out will be very imprecise and require even more tender-loving-care to make the assembly fit up correctly!

Compare that to using a tube laser.

Even at a higher hourly rate, programming and cutting will likely cost you around $55.00 per unit.

You are already saving time and money but now consider the welding.

The part will fit perfectly.

Bevels will already be in place.

All the pulling and warping and hammering and clamping will be nearly eliminated.

Using the tube laser will save you 50% per joint over your traditional methods.

If every coped and welded joint assembly cost you $200.00 per unit, you will be doing them for $100.00 per a joint assembly.

That is enough money to really consider the benefits of tube laser cutting over traditional methods.

Email us at info@allmetalsfab.com, or hop on our tube laser web site and take the tube laser challenge.

You will be the smartest guy in the room for saving your company so much money!