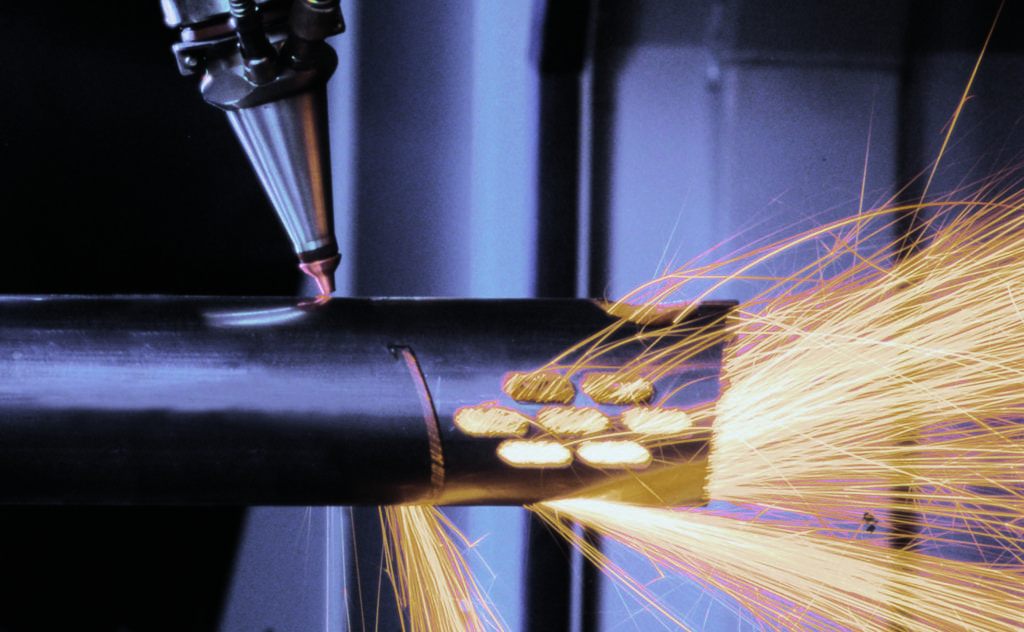

Many of our customers do not realize that All Metals Fabrication’s (AMF) Tube Laser is changing everyday fabrication—making even old-school fabrication work much easier, faster and less expensive. Ultimately, this is an enormous benefit to our customers because we can fabricate higher-quality parts while simultaneously offering a better price.

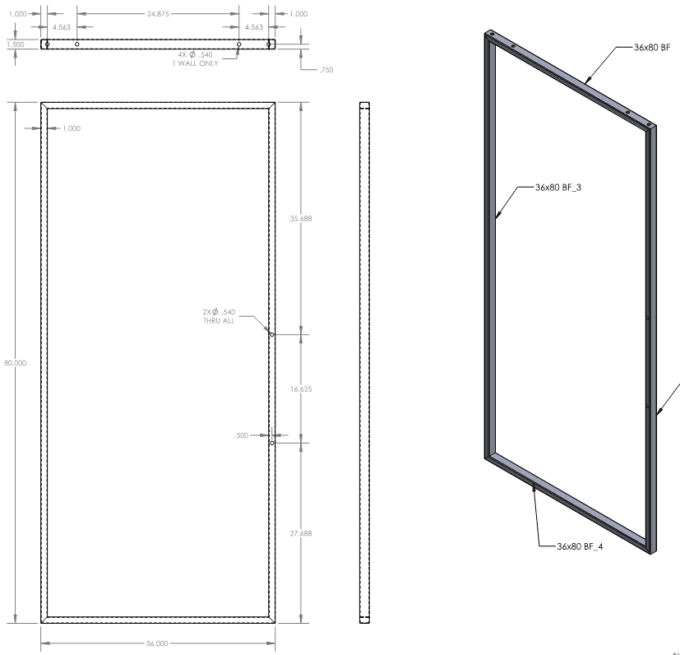

However, there will be potential problems in the traditional, old-school process as follows:

Tube Laser technology makes the process far superior.

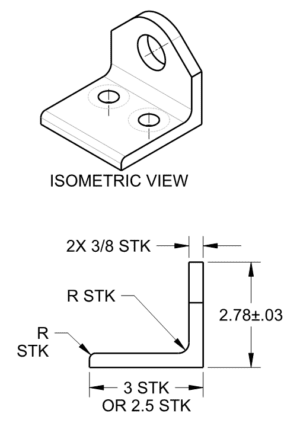

Again, here is a piece that would normally be saw-cut and drilled or machined.Problems with saw-cutting and drilling are the same as the frame above:

Tube Laser cutting benefits—even on angle shapes:

A part that might take forty-five minutes to an hour the old-school way would take less than five minutes with a Tube Laser!

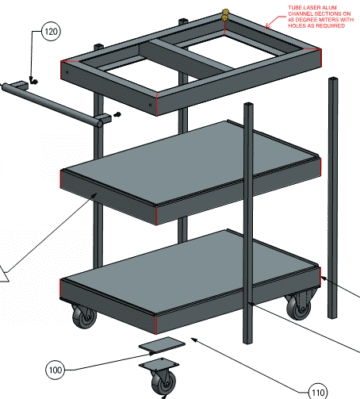

It gets better.

Weld time with Tube Laser cut channels will be 1.5 times faster than saw-cut tube because of accuracy in weld and fit-up.

Tube Laser work vastly improves traditional, old-school fabrication processes—the kind of work most shops can do—slowly, while AMF does it quickly.

And yes, Tube Lasers do cut angle.

Tube Lasers do cut channel.

Tube Lasers cut square, round and even obround, tube shapes.

Find out how AMF’s Tube Laser can benefit your traditional, old-school fabrication needs by contacting us at info@allmetalsfab.com or on https://www.allmetalsfab.com/tube-laser-cutting/.